NorthWest Engineering Service, Inc.

Key Highlights

- Many buildings experience hidden inefficiencies that silently drive-up energy use, maintenance calls, and other direct costs.

- Common issues include HVAC system drift, unbalanced airflow, building envelope leaks, and failed mechanical components, which can lead to unexpected expenses.

- Proper testing, adjustment, and system optimization can significantly reduce energy costs, improve comfort, and extend equipment life.

- Most performance issues are fixable but require targeted analysis by qualified professionals.

The Underlying Reason Buildings Become Expensive to Operate

Building owners and facility managers often assume rising utility bills are the inevitable result of aging equipment, increasing energy rates, or other indirect costs. While standard utility and maintenance bills are easy to track, they don’t tell the whole story. In reality, one of the biggest drivers of high operating costs is the accumulation of hidden performance issues. These small inefficiencies rarely announce themselves, yet they quietly increase energy consumption, strain equipment, and decrease comfort. The good news is that these issues are completely fixable.

Here are some common operational factors that could be affecting your building’s overall performance and driving up operating costs:

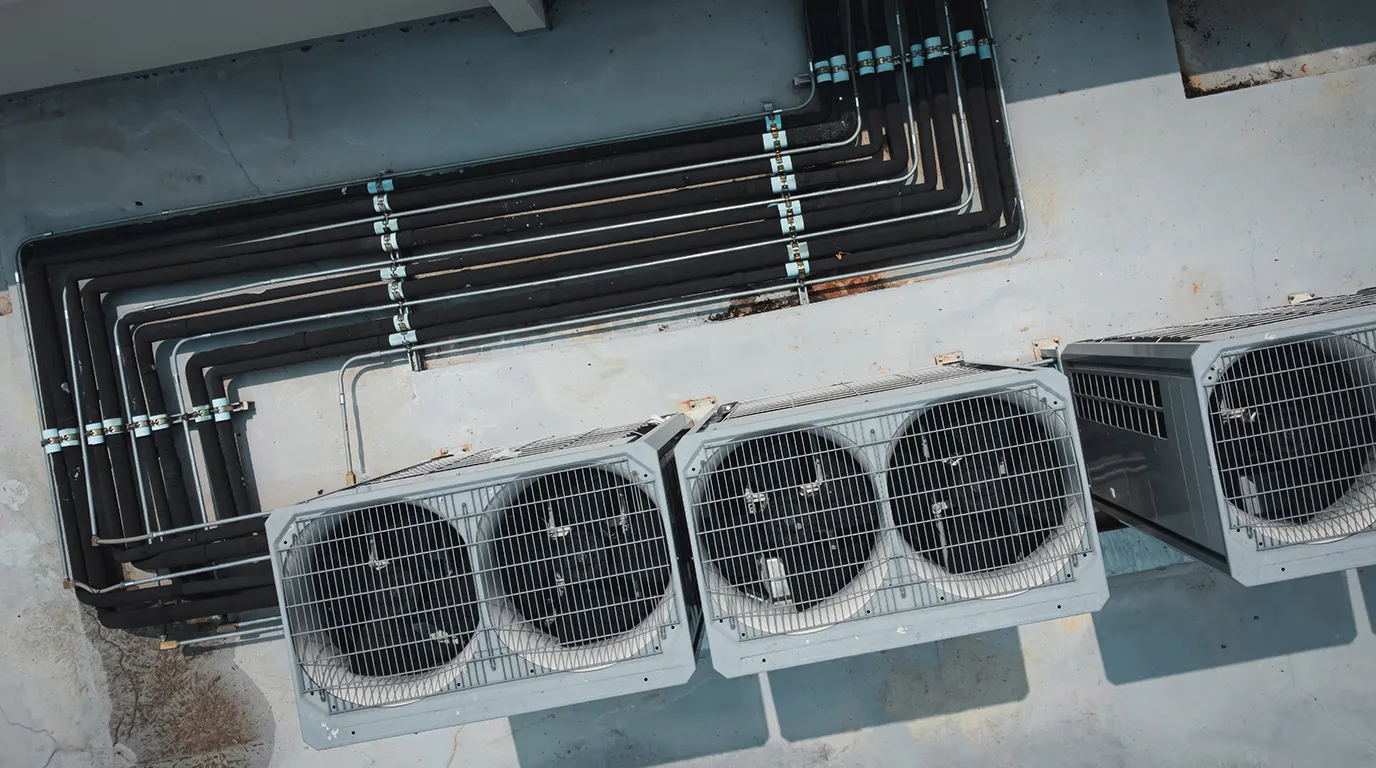

HVAC Systems Not Operating as Designed

One of the most common reasons buildings become expensive to run is that HVAC systems are no longer operating as originally designed. Over time, control sequences drift, setpoints are overridden, or components fail silently. Because HVAC components are interconnected, even one minor deviation can create a ripple effect that degrades efficiency across the entire system. When HVAC systems fall out of alignment, the result is wasted energy, occupant discomfort, and increased maintenance calls. Through Commissioning and Retro-Commissioning services, you can diagnose system deficiencies and restore your HVAC equipment to its intended performance, reducing wasted energy and unnecessary runtime.

Airflow Imbalances

Another major contributor to high operating costs is unbalanced airflow. Airflow determines how effectively heating, cooling, and ventilation are distributed throughout the building. When a building’s HVAC system doesn’t deliver air where it’s needed, fans must work harder, temperature extremes occur, and heating and cooling loads rise. These issues often lead to hot and cold spots, comfort complaints, and inefficient system performance. Testing, Adjusting & Balancing (TAB) services can help ensure airflow is adequately distributed throughout the building, improving comfort while helping HVAC equipment operate more efficiently.

Air Leaks and Poor Envelope Sealing

Air leaking through the building envelope creates another expensive problem. Leaks around doors, windows, roofs, and mechanical penetrations allow conditioned air to escape and unconditioned air to infiltrate, disrupting pressure relationships and forcing HVAC equipment to work far harder than intended. Uncontrolled air movement can introduce moisture, and over time, this moisture intrusion can lead to costly structural damage such as mold growth, wood rot, corrosion of metal components, or the deterioration of insulation. Building Envelope Testing helps identify leakage pathways, quantify their severity, and pinpoint areas where sealing or insulation improvements will yield the most significant impact, while preventing unexpected material costs.

Lack of Maintenance on Safety & Mechanical Systems

Mechanical failures and safety component issues also contribute to rising operating costs. Components such as fire and smoke dampers, control dampers, valves, sensors, actuators, and pressure switches require routine inspection and upkeep to function correctly. Deferred maintenance causes parts to stick, fall out of calibration, or fail, which disrupts airflow control and forces HVAC equipment to work harder to maintain indoor conditions. These failures often go unnoticed because the system continues to operate, albeit less efficiently and with increased energy consumption. Regular maintenance and functional testing help identify early signs of deterioration and prevent minor issues from becoming costly, long-term problems.

Outdated or Poorly Configured Controls

Many buildings also struggle with outdated or poorly configured controls. Modern HVAC systems rely heavily on sensors and automated sequences, and when these components drift out of calibration or are overridden, energy efficiency declines quickly. Equipment may operate longer than necessary, ventilation rates can deviate from intended values, and spaces may be conditioned even when unoccupied. Once again, functional testing and system calibration often help restore proper control strategies, correct inaccurate readings, and ensure that the building automation system supports overall energy performance rather than hindering it.

Oversized or Undersized HVAC Equipment

Improper equipment sizing often drives operating costs up. Oversized HVAC equipment often short-cycles, which wastes energy and leads to premature wear, while undersized equipment runs continuously as it struggles to meet demand. Both conditions raise utility expenses and reduce occupant comfort. Proper MEP design ensures HVAC equipment is correctly selected and sized to a specific project. Commissioning verifies that installed systems align with design intent and operate as efficiently as possible.

Managing and Reducing Ongoing Building Operating Costs

Now that you understand the underlying performance issues that drive up building operating costs, the next step is to address them proactively. Effective cost control goes beyond reacting to utility spikes or equipment failures; it centers on maintaining systems that operate consistently and efficiently. This shift from reactive troubleshooting to proactive system management is essential for long-term building performance.

By prioritizing system optimization, routine verification, and targeted energy-efficiency improvements, you can address the factors that drive excessive energy use and premature equipment wear. This approach reduces operational waste, improves system stability, and enhances the long-term reliability and value of the building itself.

Understanding the difference between construction (capital) costs and operating expenses is essential when considering building management strategies. Construction costs refer to the initial expenditures required to build or renovate a facility, including labor, materials, and equipment. Operating expenses, on the other hand, are the ongoing costs required to run and maintain the building, including utilities, repairs, maintenance, and general upkeep. By clarifying this distinction, building owners can decide when to resolve performance issues with operational adjustments and when to move forward with larger construction improvements.

Energy-Efficient Upgrades and Retrofits

Implementing targeted energy-efficiency improvements is one of the most effective ways to manage long-term building operating costs. Replacing outdated or underperforming components with higher-efficiency alternatives reduces mechanical strain, stabilizes indoor conditions, and lowers overall energy use. These upgrades address core performance issues such as excessive runtime, poor airflow control, or inadequate thermal resistance, all of which contribute to unnecessary utility costs. Improvements may include modernizing building controls, upgrading HVAC equipment to more efficient models, and enhancing insulation or sealing air leakage points within the building envelope. Each upgrade helps eliminate sources of waste, provides measurable reductions in operating costs, and supports more reliable system performance.

Optimizing Building Systems for Cost Savings

Beyond individual upgrades, maintaining cost-effective operations requires continuous verification that systems are functioning as intended. Commissioning ensures that new building systems operate as designed. Retro-commissioning evaluates existing buildings for performance drift caused by control overrides, sensor inaccuracies, or changes in occupancy and load conditions. Incorporating these processes into routine facility management prevents gradual declines in efficiency and reduces unnecessary energy consumption and maintenance needs. By optimizing system operations, the building can operate more consistently, with fewer performance drops and lower long-term costs. This proactive approach strengthens overall system reliability and turns building performance into an ongoing source of savings rather than a recurring operational burden.

Conclusion

Understanding the complexities of hidden building operating costs is crucial for effective financial management. By recognizing the less obvious factors that can drive up costs, property owners and managers can develop more effective cost-control strategies. Commissioning agents can help uncover those hidden operational inefficiencies, empowering facility managers to take the required action to reduce expenses and unexpected costs.

Effective project budgeting, combined with a focus on building system optimization, enhances overall project profitability. Through accurate financial planning and the application of value engineering principles, businesses can identify and mitigate hidden expenses, thereby optimizing building operations and maintaining their profit margins. Standard accounting methods for tracking building development and construction expenses include job costing and percentage-of-completion accounting, which enable businesses to monitor costs and revenues in real time and ensure precise expense allocation. Ultimately, a comprehensive approach to managing these hidden construction project expenses will foster long-term stability and success in the competitive landscape of commercial real estate.

Frequently Asked Questions

How can energy efficiency improvements impact the overall operating expenses of a building?

Energy efficiency improvements directly reduce a building’s energy consumption, leading to lower utility bills. This form of cost management reduces monthly operating costs, reduces equipment wear, and improves the property’s long-term financial performance by minimizing wasted resources.

How can property owners effectively track and manage ongoing building expenses?

Property owners can manage expenses by using building management systems to monitor energy use, conducting regular energy audits, and implementing a preventive maintenance schedule. Partnering with professionals for services like Commissioning provides the data needed for effective financial management and cost control.

Are there specific management practices that can help reduce hidden operating costs?

Yes. Proactive management practices like regular Testing, Adjusting, and Balancing (TAB), ongoing Commissioning, and building envelope testing are crucial. These practices identify and correct inefficiencies before they significantly increase project costs, providing essential cost control over hidden operational issues.