NorthWest Engineering Service, Inc.

Managing buildings and facilities is complex; even experienced owners or facility managers can fall into common traps. Here are ten mistakes that often come up and how you can avoid them:

Managing buildings and facilities is complex; even experienced owners or facility managers can fall into common traps. Here are ten mistakes that often come up and how you can avoid them:

1. Unqualified work that voids your warranty

Unqualified work on equipment or materials can quickly void a manufacturer’s warranty, leaving building owners on the hook for costly repairs. Unlicensed installers often skip critical standards, increasing the risk of failed inspections, premature system failures, and accelerated equipment wear. By the time the facility manager tries to file a warranty claim, it is often too late. The manufacturer will likely deny coverage if a valid contractor license number wasn’t included during warranty registration. Even when certified contractors perform the work, improper installation can still result in a voided warranty. This is why it is so important to have a qualified manufacturer’s representative on site to verify and sign off on the installation. Their expertise can help catch issues early and ensure the equipment is installed correctly, protecting it under warranty.

Unqualified work on equipment or materials can quickly void a manufacturer’s warranty, leaving building owners on the hook for costly repairs. Unlicensed installers often skip critical standards, increasing the risk of failed inspections, premature system failures, and accelerated equipment wear. By the time the facility manager tries to file a warranty claim, it is often too late. The manufacturer will likely deny coverage if a valid contractor license number wasn’t included during warranty registration. Even when certified contractors perform the work, improper installation can still result in a voided warranty. This is why it is so important to have a qualified manufacturer’s representative on site to verify and sign off on the installation. Their expertise can help catch issues early and ensure the equipment is installed correctly, protecting it under warranty.

2. Not requiring TAB (Testing, Adjusting, and Balancing)

After installing new HVAC equipment, the job isn’t truly done until the systems are appropriately tested, adjusted, and balanced (TAB). Without TAB, even well-designed heating and cooling systems may not perform as intended. Some rooms might get too much airflow, while others get too little, or you could have an HVAC leak that results in significantly higher energy use. The TAB process involves measuring and adjusting air and water flows to meet the design requirements, using instruments and sensors to verify temperatures, pressures, and speeds. Skipping this step can result in comfort complaints, indoor air quality issues, and energy inefficiencies that could have been easily avoided with a post-installation balance.

After installing new HVAC equipment, the job isn’t truly done until the systems are appropriately tested, adjusted, and balanced (TAB). Without TAB, even well-designed heating and cooling systems may not perform as intended. Some rooms might get too much airflow, while others get too little, or you could have an HVAC leak that results in significantly higher energy use. The TAB process involves measuring and adjusting air and water flows to meet the design requirements, using instruments and sensors to verify temperatures, pressures, and speeds. Skipping this step can result in comfort complaints, indoor air quality issues, and energy inefficiencies that could have been easily avoided with a post-installation balance.

3. Prioritizing aesthetics over functionality in the design phase

It’s easy to prioritize flashy architecture over functionality, but that can come at a high cost. Complex designs often require equally complex duct and piping layouts, which increase fan and pump energy due to higher pressure drops. More pressure drop means more money. Missteps, such as undersized HVAC spaces or floor-to-ceiling windows that cause significant heat loss, lead to inefficiencies, costly redesigns, and poor occupant experience. Striking buildings may turn heads, but what people rely on is how the space works. Involving engineers early and adopting a design approach that prioritizes functionality and long-term cost savings while maintaining the intended building vision will prevent headaches down the road.

It’s easy to prioritize flashy architecture over functionality, but that can come at a high cost. Complex designs often require equally complex duct and piping layouts, which increase fan and pump energy due to higher pressure drops. More pressure drop means more money. Missteps, such as undersized HVAC spaces or floor-to-ceiling windows that cause significant heat loss, lead to inefficiencies, costly redesigns, and poor occupant experience. Striking buildings may turn heads, but what people rely on is how the space works. Involving engineers early and adopting a design approach that prioritizes functionality and long-term cost savings while maintaining the intended building vision will prevent headaches down the road.

4. Failing to validate vendor work before payment

Trusting your contractors is important, but trust should be verified. Paying in full before confirming the work was done right can cost you. Too often, facility teams sign off as soon as someone says “all set,” without a proper walk-through or test. If something was missed, you’ve lost leverage to fix it. Always validate the work first—do a joint inspection, test the equipment, or bring in a third party if needed such as a commissioning agent (CxA) to ensure building systems works as intended. Make sure your contract allows for a final inspection, and don’t release final payment until the job meets your expectations. This isn’t about being difficult, it’s about protecting your investment.

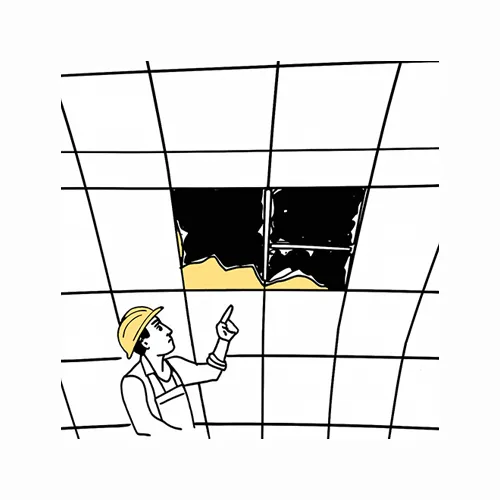

5. Delaying fire safety compliance until the final stages

Fire safety compliance is not something to address at the last minute. If you forget to loop in federal, state, and local Authorities Having Jurisdiction (AHJ) during a project, you risk finding out late that something doesn’t meet code. AHJs are entities responsible for enforcing codes and standards, such as fire marshals or building inspectors. Forgetting this step often leads to costly last-minute changes or delays in getting your occupancy certificate. For instance, life safety systems like alarms, sprinklers, and fire dampers should be reviewed and tested. Ensuring your building’s fire smoke dampers are thoroughly inspected, documented, and compliant with fire codes and NFPA standards will reduce the risk of fire and smoke spread during an emergency. Engaging AHJs helps catch the requirements you might overlook, keeping your facility safe and up to code without last-minute surprises.

Fire safety compliance is not something to address at the last minute. If you forget to loop in federal, state, and local Authorities Having Jurisdiction (AHJ) during a project, you risk finding out late that something doesn’t meet code. AHJs are entities responsible for enforcing codes and standards, such as fire marshals or building inspectors. Forgetting this step often leads to costly last-minute changes or delays in getting your occupancy certificate. For instance, life safety systems like alarms, sprinklers, and fire dampers should be reviewed and tested. Ensuring your building’s fire smoke dampers are thoroughly inspected, documented, and compliant with fire codes and NFPA standards will reduce the risk of fire and smoke spread during an emergency. Engaging AHJs helps catch the requirements you might overlook, keeping your facility safe and up to code without last-minute surprises.

6. Siloed team knowledge

Siloed knowledge is a significant risk in facility and engineering teams. When only a few individuals hold key system details, troubleshooting steps, or vendor contacts, their absence can leave operations exposed. Whether due to time off, turnover, or retirement, losing that knowledge can lead to downtime, safety issues, and expensive retraining. To break down silos, teams should prioritize cross-training, mentorship, and precise documentation. Centralized tools, such as a CMMS, ensure that critical information is accessible and up-to-date. Rotating responsibilities and running training drills further strengthen team readiness, ensuring operations stay smooth, even during staff changes or emergencies.

Siloed knowledge is a significant risk in facility and engineering teams. When only a few individuals hold key system details, troubleshooting steps, or vendor contacts, their absence can leave operations exposed. Whether due to time off, turnover, or retirement, losing that knowledge can lead to downtime, safety issues, and expensive retraining. To break down silos, teams should prioritize cross-training, mentorship, and precise documentation. Centralized tools, such as a CMMS, ensure that critical information is accessible and up-to-date. Rotating responsibilities and running training drills further strengthen team readiness, ensuring operations stay smooth, even during staff changes or emergencies.

7. Neglecting preventive maintenance

Neglecting preventive maintenance is one of the most expensive mistakes facility teams can make. Without it, systems like HVAC, plumbing, and electrical wear down, leading to breakdowns, costly repairs, and shorter lifespans. Poor maintenance also increases safety risks, code violations, and tenant complaints. Regular inspections and servicing help catch small issues early, boost efficiency, and extend equipment life. A solid maintenance plan and trained staff are key to keeping operations reliable and costs under control.

Neglecting preventive maintenance is one of the most expensive mistakes facility teams can make. Without it, systems like HVAC, plumbing, and electrical wear down, leading to breakdowns, costly repairs, and shorter lifespans. Poor maintenance also increases safety risks, code violations, and tenant complaints. Regular inspections and servicing help catch small issues early, boost efficiency, and extend equipment life. A solid maintenance plan and trained staff are key to keeping operations reliable and costs under control.

8. Approving modifications without understanding load impact & scope

Even small facility changes can create big problems if not carefully reviewed. Approving a retrofit or occupant request without assessing system impacts can lead to issues like overloaded electrical or HVAC systems, structural strain, or code violations. For example, adding a commercial kitchen or removing a wall can affect ventilation, plumbing, or fire safety. Always consult an engineer to understand utility demands, structural effects, and compliance needs before making changes. This helps avoid costly surprises down the line.

Even small facility changes can create big problems if not carefully reviewed. Approving a retrofit or occupant request without assessing system impacts can lead to issues like overloaded electrical or HVAC systems, structural strain, or code violations. For example, adding a commercial kitchen or removing a wall can affect ventilation, plumbing, or fire safety. Always consult an engineer to understand utility demands, structural effects, and compliance needs before making changes. This helps avoid costly surprises down the line.

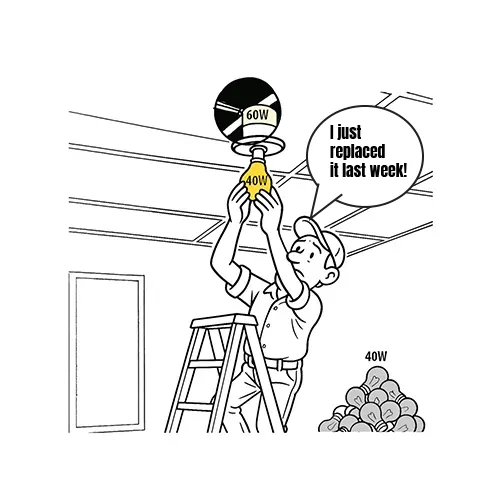

9. Failing to keep accurate maintenance logs

Many facility teams skip detailed maintenance logs, but that short-term time saver creates long-term problems. Without records, diagnosing issues becomes more challenging, and recurring failures may go undetected. You might miss patterns, for instance, if the same pump fails every summer, but if no one ever records it, the root cause can go undetected. Logs serve as medical records for equipment, tracking what was done, when, by whom, and with which parts. They help ensure preventive maintenance isn’t missed and support warranty claims or safety audits with documented proof of upkeep.

Many facility teams skip detailed maintenance logs, but that short-term time saver creates long-term problems. Without records, diagnosing issues becomes more challenging, and recurring failures may go undetected. You might miss patterns, for instance, if the same pump fails every summer, but if no one ever records it, the root cause can go undetected. Logs serve as medical records for equipment, tracking what was done, when, by whom, and with which parts. They help ensure preventive maintenance isn’t missed and support warranty claims or safety audits with documented proof of upkeep.

10. Treating building commissioning as optional

Some owners see Building Commissioning (Cx) as a “nice-to-have,” but it’s essential. Cx is a quality assurance process that ensures building systems, such as HVAC, electrical, and controls, are installed and functioning as intended. Skipping it can let hidden issues slip through, like uncalibrated sensors or backup systems that fail in an emergency. Commissioning includes design reviews, testing, and training to ensure everything runs efficiently in the long term. Done right, it often pays for itself by avoiding costly fixes and improving performance and energy savings.

Some owners see Building Commissioning (Cx) as a “nice-to-have,” but it’s essential. Cx is a quality assurance process that ensures building systems, such as HVAC, electrical, and controls, are installed and functioning as intended. Skipping it can let hidden issues slip through, like uncalibrated sensors or backup systems that fail in an emergency. Commissioning includes design reviews, testing, and training to ensure everything runs efficiently in the long term. Done right, it often pays for itself by avoiding costly fixes and improving performance and energy savings.