NorthWest Engineering Service, Inc.

“Failing to Plan is Planning to Fail”

Purpose of Fire Systems and Why Testing Them Is Essential

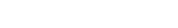

NFPA fire smoke damper testing and maintenance are critical parts of modern fire safety. Throughout history, catastrophic fires have driven sweeping changes in fire safety codes and building standards. In 1903, the Iroquois Theater fire in Chicago, which claimed over 600 lives, exposed flaws in emergency exits and curtain materials, influencing egress and fire curtain regulations. The 1911 Triangle Shirtwaist Factory fire and the 1942 Cocoanut Grove Nightclub fire led to reforms in fire escapes, exit lighting, and occupancy limits. Together, these events highlighted the absence of basic fire protection, leading to the widespread adoption of fire safety systems, such as sprinklers, fire alarms, and emergency exits.

Later fire disasters, such as the 1980 MGM Hotel fire and the 2003 Station Nightclub fire, occurred in buildings that had fire protection systems in place, yet those systems failed due to a lack of maintenance, testing, and improper installation. As a result, modern fire codes have shifted not only toward requiring robust safety systems, but also toward ensuring their reliability through enhanced inspection, maintenance, and testing standards.

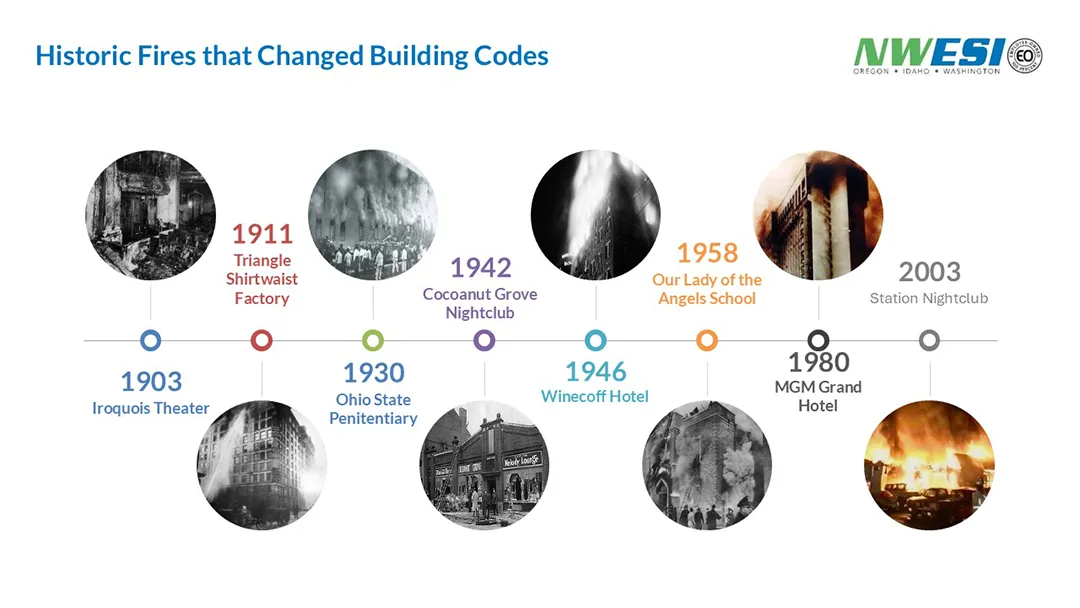

Today, modern buildings rely on multiple fire protection systems, including alarms, sprinklers, fire pumps, kitchen hood suppression, rated partitions and doors, dampers, HVAC shutdown, pressurization systems, and smoke removal. These systems are designed to protect lives and property, but without proper maintenance, they often fail when needed. One failure can trigger others, which can allow fire to spread and increase risk and liability.

Contractors are typically responsible for testing, but the quality and documentation vary greatly. Some tests go undocumented, are performed incorrectly, or are signed off without being completed. Therefore, systems may pass on paper but fail in practice.

Authorities Having Jurisdiction (AHJs) also test fire systems; however, the level of review depends on the specific system. For example, Fire alarms and pumps get more attention, while dampers and HVAC shutdowns are often overlooked. Third parties must inspect smoke control systems in high-rises, but even with this requirement, gaps in oversight can compromise safety.

Types of Fire System Failures and Their Consequences

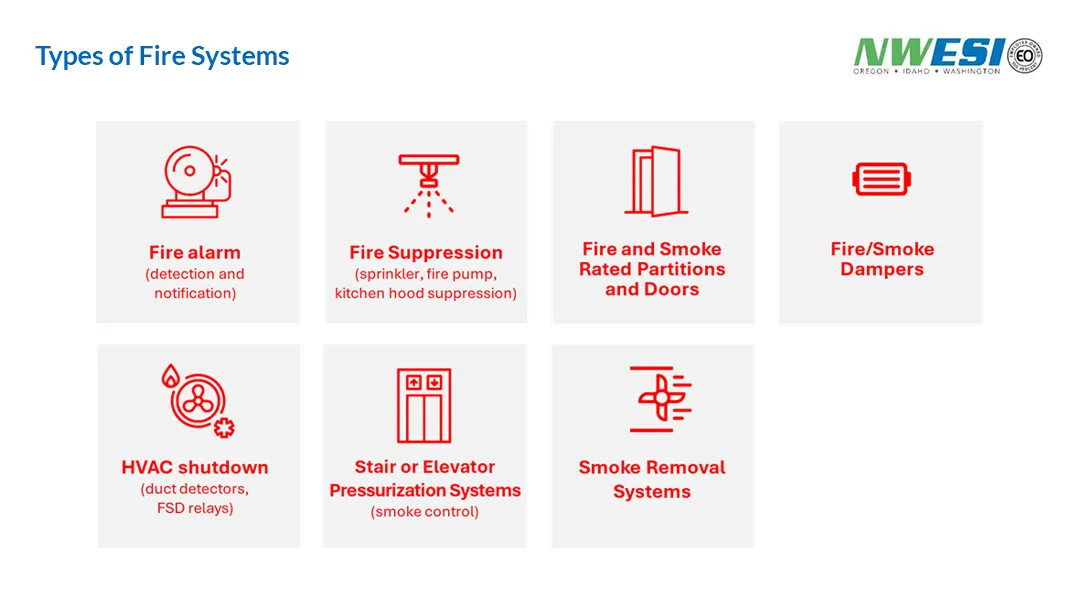

The Bathtub Curve is a useful model for understanding when fire system components are most likely to fail. Specifically, it breaks down failure probability into three phases:

-

- Early Life Mortality: Early failures caused by defective components, improper installation, or the use of inappropriate parts for the system.

- Normal Life: During this phase, random failures may occur due to environmental exposure or insufficient maintenance.

- Wear-Out: As components reach the end of their lifespan, wear and tear result in an increased failure rate.

The Bathtub Curve of Fire System Failures

Common causes of fire system failures include:

- Improper installation

- Lack of routine maintenance

- Physical damage (from remodeling or neglect)

- Environmental stress (humidity, temperature extremes, corrosion)

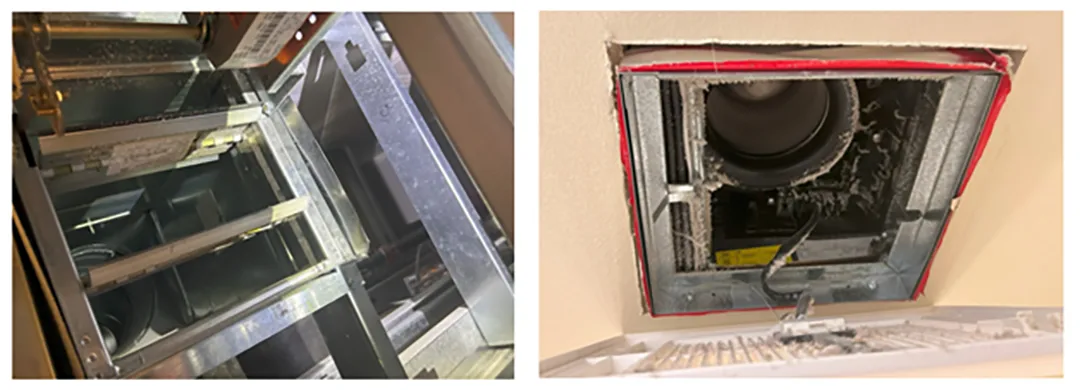

- Mechanical issues such as broken linkages or rusted pivots

- Obstructions from dust or debris

- Faulty actuators or fusible links

- Misaligned or broken tracks in dampers

Fire and smoke damper failures are especially critical. If these components don’t close as designed, fire and smoke can quickly spread through ventilation systems, endangering occupants and property. Beyond the safety risk, building owners may face legal liability, insurance complications, code violations, and costly delays in occupancy certification. Poorly functioning fire protection systems can also require expensive last-minute design changes.

Mitigating Fire Safety System Failures Through Standardized Testing

The most effective way to mitigate fire safety failures is through diligent, routine inspections guided by the National Fire Protection Association (NFPA) standards. Because of this, the Bathtub Curve shows higher failure rates during both early use and end-of-life, inspections and testing must occur both at installation and at regular intervals thereafter. The NFPA standards, referenced in fire codes, define inspection intervals and procedures based on lessons learned from past fire disasters.

Clearly assigning responsibility is critical to ensuring fire and life safety systems perform as intended. Initial inspections and testing are typically conducted by the construction team during installation to verify proper setup and functionality. Once the building is operational, the responsibility shifts to the building owner or operator, who must oversee ongoing inspections and testing. In most cases, these inspections closely resemble the original testing procedures.

Key testing procedures include:

Fire-Alarm Testing

- Simulate AC power loss and low battery

- Test communication pathways and sample detection devices

- Verify responses across systems (annunciators, audio/visual devices, HVAC, elevators, doors)

Fire-Suppression System Testing

- Perform fire pump flow tests and simulate power failures

- Operate tamper valves, verify system alarms, and test dry and pre-action systems under real conditions

Fire-Barrier Testing

- Verify continuous barriers, proper labeling, and sealed penetrations with intumescent materials

Fire/Smoke-Rated Door Testing

- Confirm ratings, visible labels, integrity of glazing, and proper clearances

- Test door closers, hold-opens, and coordination devices

Fire/Smoke Damper Testing

- Verify access, label, and conduct operational tests

- Simulate tripping mechanisms and check end switch functionality

Stair and Elevator Pressurization System Testing

- Ensure fans start, doors close, pressure levels are correct, and emergency power systems function

Smoke Control Special Inspection

- Inspect installation, and verify leakage testing

- Perform integrated testing of smoke control systems

- Submit certified reports to the AHJ for compliance

Ongoing Testing of Existing Components

- “If it isn’t documented, it didn’t happen.”

- Records must include:

- Test date

- Tested components

- Results

- Test performer

- Documentation is often required by AHJs, insurers, and certifiers

Inspection Frequencies and NFPA Standards

| NFPA 25: Water-Based Systems |

Weekly: Backflow preventers, control valves (if not locked), pump checks

Monthly: Gauges, no-flow tests for electric/diesel pumps Quarterly: Waterflow alarms, valves, fire department connections Annually: Sprinklers (visual), dry valves, hangers, FDCs Every 3 Years: Dry valve full-flow test Every 5 Years: Gauge and sprinkler replacement, alarm valve maintenance, check valves, internal backflow inspection |

| NFPA 72: Fire Alarm Systems |

Weekly: Unmonitored systems

Monthly: Battery checks Quarterly: Supervisory signals, radiant/video detectors Semiannually: Initiating devices, appliances, remote annunciators Annually: Alarm control panels, station transmitters, full initiating device simulation |

| NFPA 80 & 105: Doors and Dampers |

Annually: Fire and smoke doors must be inspected and tested. This includes checking, intact gasketing, clearances around doors, and functional hardware

Every 4–6 Years: Fire and smoke dampers must be tested for proper operation, typically every 4 years in most facilities and every 6 years in hospitals. This involves ensuring that the damper fully closes upon system activation and that all components are functioning as intended

|

| NFPA 80 & 92: Smoke Control Systems |

Intervals vary by system type and jurisdiction—typically tested during commissioning and annually thereafter |

| NFPA 101: Life Safety Code |

Test intervals vary, but this applies to egress, emergency lighting, signage, and integration with fire systems |

Conclusion

Fire protection systems are critical safeguards that stand between building occupants and devastating consequences. However, the system is only as reliable as its weakest component. Ultimately, history and engineering show one solution: rigorous and ongoing testing. By adhering to NFPA standards, implementing thorough inspections, and ensuring accurate documentation, building owners and facilities professionals can significantly reduce the risk of fire system failures.